ZIPPIAN

QUALITY

Quality control

ZIPPIAN conducts thorough quality control under a clean environment in each manufacturing process from the supply and demand process of raw and subsidiary materials to shipment in order to supply hygienic and safe products that customers can use with confidence and we are working hard to further strengthen this.

In order to continue to practice and realize this, we have established our own basic policy for quality management and safety, and in accordance with this policy, we thoroughly control the quality of products to be delivered to customers. All employees are striving to improve quality by raising awareness of the quality and safety of their zippers and packaging that use them.

In addition, we are equipped with a flexible and fast systematic production management system, and operate an appropriate inventory management and warehouse management system so that we can always respond accurately to urgent customer requests in a timely manner.

Through our long-established production, quality, and inventory management system, we are able to supply our products with safe and high-quality products immediately when required by our customers.

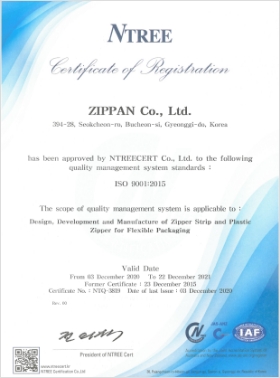

Quality Management System (QMS)

ISO 9001 is one of the most widely used management system standards around the world today and is an international standard.

We are always striving to improve quality to provide our customers with products that can be used with confidence. As part of that, we have obtained ISO 9001:2015 Quality Management System (QMS) certification from a third-party certification from a third-party certification body, and operate our quality management system accordingly.

Quality Assurance (QA)

-

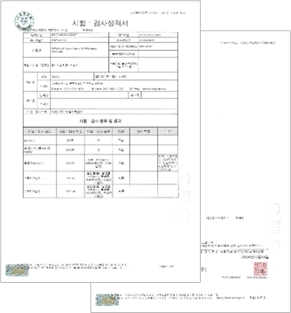

용출시험검사

-

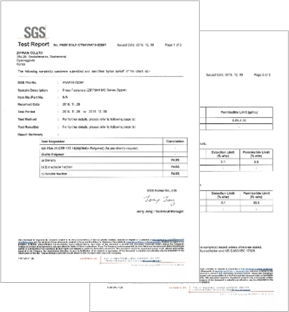

US FDA TEST

-

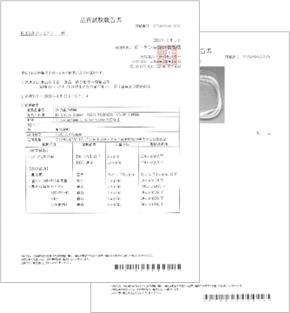

日本材質溶出試験検査

-

EU FOOD CONTACT TEST

In order to provide safer products and to ensure customer safety, we regularly conduct objective

product safety inspections through third-party organizations, and provide them to our customers.

Quality Hygiene Activities

In order to provide safe zippers to customers, we have acquired FSSC22000 (Food Safety Management System) to produce zippers.

The world now has a growing need for safer and better food (products). And there is a growing awareness of whether the products produced are produced in socially and environmentally responsible ways.

The FSSC 22000 is a system developed by integrating widely adopted standards to define food safety certification systems suitable for the entire food industry. It is a food safety certification system that is applied around the world with "improvement of food safety effects and efficiency," "strong risk factor analysis based on HACCP," and "risk management methodology.

In 2023, we obtained the FSSC22000 certification, comply with it, and produce zippers suitable for food packaging.

Zippian has been manufacturing safe and confidence zippers for 30 years since

foundation that anyone can feel "Zippian is safe" when it comes to flexible packaging field.

SUSTAINABILITY

Prioritizing the environment so that the next generation can live a healthy life on a clean planet

is the value of the environment that ZIPPIAN pursues.

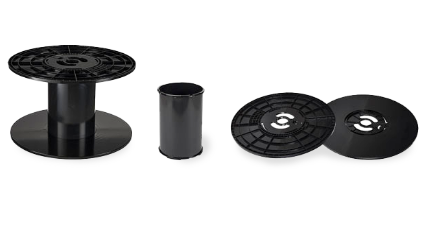

Recyclable all paper bobbins and Reusable plastic bobbins are ZIPPIAN's will to think about the environment.

Recyclable all paper bobbin

Reusable plastic bobbin

From Nature, To Nature